|

Case studies include information about actual recoveries

completed within our lab. You may find similar symptoms to a problem

you are having with your drive. Here are a couple of recent cases:

• 250GB

Seagate Clicking

• 1TB Raid

0

|

|

|

**No Evaluation Fees / No Attempt Fees** Free evaluation and free external hard drive with every successfull recovery. You pay nothing unless your data is recoverable. Call now for a free quote: 1-800-717-8974. |

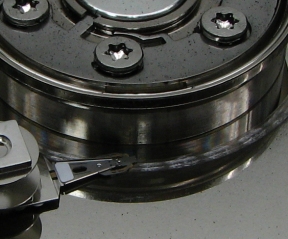

Hard Disk Platters

The

platters of a hard drive actually hold your data. The image on the left

illustrates what a platter looks like after it has been scored by a head

crash. The

platters of a hard drive actually hold your data. The image on the left

illustrates what a platter looks like after it has been scored by a head

crash.

The magnetic surface of each platter is divided into magnetic regions

less than a micrometer in size. Each of these regions makes up a single

binary unit of information. A binary region on a hard drive platter (as

of 2006) is about 200-250 nanometers wide (within the radial direction

of the platter) and extends about 25-30 nanometers in the down-track direction.

This comes to about 100 billion bits (100 gigabits) per square inch of

hard drive platter area. The materials which make up the magnetic layer

are usually a cobalt-based alloy. Today, each of these magnetic regions

within the hard drive is composed of a few hundred magnetic grains. It

is these magnetic grains which become magnetized when data is written

to the drive. It is possible that in the future, drive manufacturers may

use different systems to create the magnetic regions.

The actual platter is most often made of aluminium or glass substrate.

After the platter is machined, it is then coated using a vacuum deposition

process called magnetron sputtering. Vacuum deposition is a wonder all

on it's own, as this process deposits material, atom by atom or molecule

by molecule onto a solid surface. The coating itself is comprised of mostly

non-magnetic metallic alloys which is very complex in structure. There

is also a protective coating that is carbon based and is applied in the

same manner. Finally, a thin lubricant layer, approximately one nanometer

is applied by dipping the platter into a solution. The platter is then

allowed to cure and receives a final buff to remove any defects in the

surface. A special sensor examines the platter surface for any remaining

defects.

Platter surfaces have a mirror finish. Any contamination can render the

contaminated area of the platter unreadable. The surface of the platter

is especially succeptible to finger prints with even the slightest touch.

That is why careful handling of a hard drive is critical during the recovery

process, and all recovery work must be completed in a clean room environment.

When a hard drive suffers a physical

failure, such as a head

crash, the platters can sometimes become scored due to the head coming

in contact with the platter and grinding the surface. In these cases it

is rare that data will be recoverable. For more information, please call

1-800-717-8974.

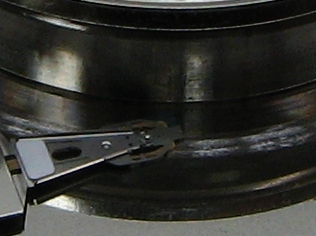

Scored platter due to a hard

drive crash. Notice the debris

radiating around the cut in the platter. This debris often

causes even more damage to the platter.

A closer look.

Even closer.

|

**No Evaluation Fees / No Attempt Fees** Call now for a free quote: 1-800-717-8974. For over a decade we have been dedicated to recovering data for clients across the globe.

|

|

|

Get setup as a reseller and get 10% off of all our

recovery services. 10% may not seem like a lot, but when you factor

in that we are already one of the lowest priced data recovery providers,

it can mean you have room for a substantial mark up.

|

|

ACS Data Recovery

1005 Marlandwood Rd. Suite 117

Temple, TX 76502

Get Detailed Driving Directions

Toll-Free: 1-800-717-8974

International: +1-254-774-8282

Fax: 1-800-717-8974

Email: info@acsdata.com

|

|